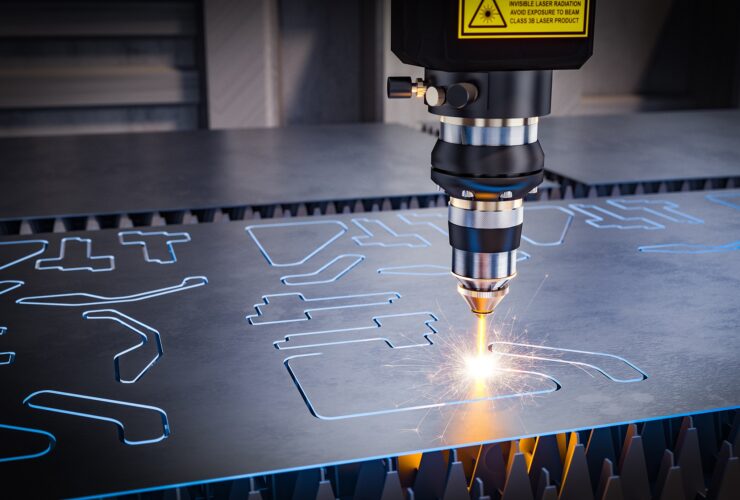

In an era where precision and customization reign supreme, the value of custom-milled parts has surged across diverse sectors. These meticulously crafted components are not merely functional; they represent the very heart of innovation, driving efficiency and performance in industries as varied as aerospace, automotive, and medical.

Imagine the intricate interplay of technology and design, where one small piece can dictate the success of a complex system. Custom milling is not just about producing parts; it’s about crafting tailored solutions that meet the unique demands of each application.

In this article, we will delve into the top three applications that showcase the remarkable impact of custom-milled parts, illuminating their pivotal roles and the transformative potential they hold for the future of manufacturing.

Aerospace Industry: Precision Components for Enhanced Performance

In the aerospace industry, the demand for precision components has reached unprecedented heights, driven by the relentless pursuit of enhanced performance and reliability. Custom-milled parts play a pivotal role, as they cater to the stringent specifications of aircraft and spacecraft, where even the slightest deviation can lead to catastrophic failures.

These components are meticulously crafted from high-grade materials, ensuring they can withstand extreme temperatures and pressures encountered in flight. Imagine complex assemblies like turbine blades and avionics housings, each requiring a unique blend of artistry and engineering prowess.

This intricate dance of design and manufacturing not only enhances fuel efficiency but also extends the overall lifespan of critical systems, ultimately contributing to safer and more efficient aerial transport. The fusion of innovative technologies, such as computer-aided design (CAD) and advanced machining processes, has revolutionized the creation of these bespoke parts, allowing for unparalleled precision that was once deemed impossible.

As the aerospace sector continues to evolve, the role of custom-milled parts remains a cornerstone for pushing the boundaries of what is possible in air travel.

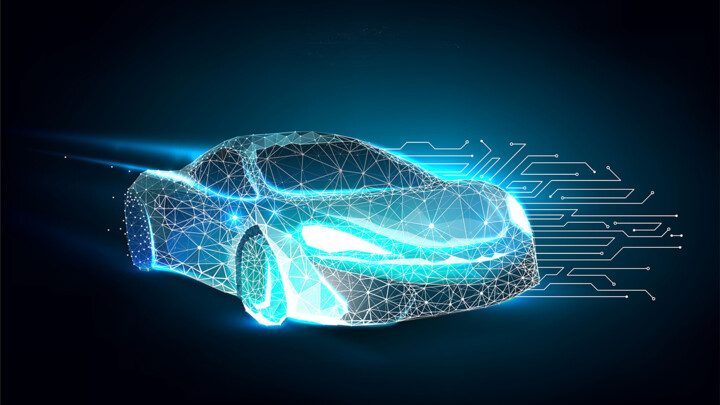

Automotive Industry: Tailored Solutions for Efficiency and Safety

In the automotive industry, custom-milled parts are revolutionizing the landscape by providing tailored solutions that enhance both efficiency and safety. The precision engineering behind these components addresses the unique demands of modern vehicles, allowing for intricate designs that cater to specific performance criteria.

Think of high-performance engine components—crafted with exacting standards, they can significantly boost efficiency while reducing weight and improving fuel consumption. Moreover, safety-critical elements like braking systems and suspension parts benefit enormously from bespoke milling; their design can integrate advanced features that meet rigorous safety regulations, ensuring reliability when it matters most.

As automakers continue to prioritize innovation, the adaptability of custom-milled parts stands out, offering not just enhancements in functionality but also paving the way for the future of sustainable and safer driving experiences.

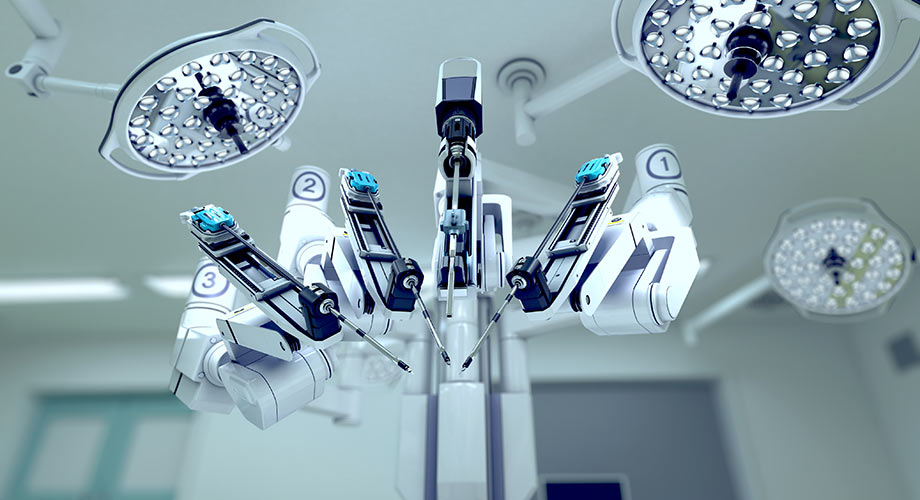

Medical Devices: Custom Parts for Innovative Healthcare Solutions

In the realm of healthcare, custom-milled parts have emerged as a cornerstone for enhancing medical devices, driving innovation where precision and performance are paramount. From bespoke surgical instruments tailored for specific procedures to specialized implants designed for individual patients, the adaptability of custom components allows for a level of personalization that standard manufacturing simply cannot achieve.

These intricately crafted parts can incorporate advanced materials that improve biocompatibility and durability, ultimately leading to better patient outcomes. Moreover, as the demand for smart medical devices grows, custom milled components can be integrated with cutting-edge technology, enabling functionalities such as real-time monitoring and data collection.

This fusion of bespoke manufacturing and technological advancement not only revolutionizes how care is delivered but also provides healthcare professionals with tools that empower them to respond dynamically to patient needs.

Conclusion

In conclusion, the versatility and precision of custom-milled parts make them indispensable across various industries, from aerospace to medical equipment and automotive manufacturing. By leveraging advanced milling machining components, companies can achieve tailored solutions that meet specific design requirements and enhance overall product performance. As the demand for innovative and high-quality components continues to rise, the role of custom milling will only grow in importance, driving efficiency and opening new avenues for technological progress.

Embracing these advanced applications not only supports industry growth but also fosters a culture of customization that can lead to more sustainable and effective manufacturing practices.